Pros

Fully transparent body lets users see water boiling, which enhances visual appeal and user experience.

No coatings are needed; glass is naturally inert.

Glass does not discolor over time.

Challenges

Glass is inherently more fragile than metal; even tempered glass can crack from impact or thermal shock if handled poorly.

Packaging, storage, and international logistics must emphasize breakage protection.

Performance

The glass body does not add thermal performance advantages; heat transfer occurs primarily at the metal heating plate.

Pros

Excellent durability and resistance to impact during daily use and long-distance shipping.

Efficient heat conduction when designed with proper internal contact surfaces.

Stainless steel is widely accepted in safety-critical applications such as professional beverage equipment.

Challenges

The interior finish and grade of stainless steel matter for taste and corrosion performance; poor grades can lead to metallic taste or spotting.

Exterior surfaces may need finishes or coatings to avoid fingerprints.

Performance

Stainless steel can help retain heat better once boiling is complete.

Preferred in high-frequency use environments due to thermal and mechanical stability.

Glass

Visually appealing but structurally weaker than steel.

More prone to breakage during transport and handling if not packed well.

Sensitive to thermal stress from rapid temperature changes.

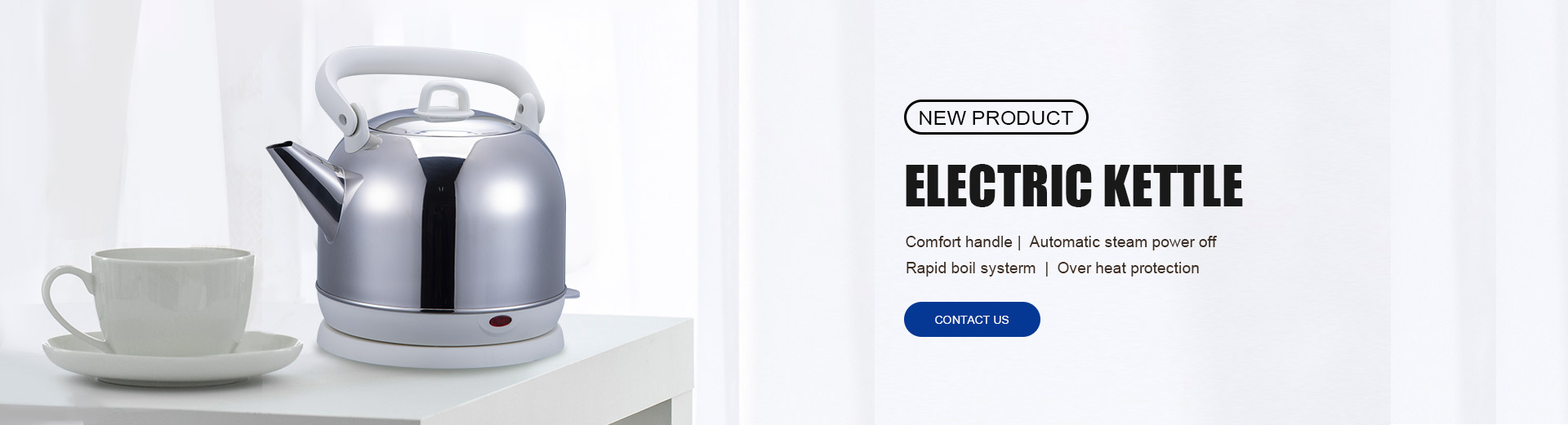

Stainless Steel

Highly robust against drops, knocks, and vibration.

Consistent thickness and welding quality contribute to product longevity.

Manufacturing consistency in steel parts reduces return rates in export markets.

Manufacturing Insight

From a production and quality-control standpoint, Stainless Steel Kettles typically experience lower damage rates through packaging, transport, and repeated use.

Glass

Chemically inert and does not interact with water.

Offers a clean, pure contact surface with no coatings.

Stainless Steel

Safe when using high-grade food-grade material (e.g., 304 or equivalent).

Resistant to corrosion and oxidation.

If correctly processed, stainless steel interiors do not alter taste or release substances.

Key Focus

The material grade and surface finish quality matter more than the base material itself for health safety.

Glass

Heat transfer depends entirely on the concealed heating plate design.

Users see water circulation, but the boiling process timing is similar to stainless steel.

Stainless Steel

Tends to retain heat slightly better post-boil, which can provide minor energy savings in batch scenarios.

Consistent contact between water and heating surface enhances heating efficiency.

Glass

Scale and hard water deposits are highly visible, prompting users to clean more regularly.

Aesthetically satisfying when clean but shows stains easily.

Stainless Steel

Scale is less visible and cleanup is straightforward.

Interior surfaces tolerate descaling agents without surface damage.

User Behavior Impact

Regular cleaning—especially in hard-water regions—is essential for performance efficiency regardless of material.

Glass

Transparent walls can amplify the sound of boiling bubbles.

Visual and audio cues may feel “stronger,” which some users associate with performance.

Stainless Steel

Body structure tends to dampen noise, resulting in a quieter boiling experience.

From a manufacturing testing standpoint, stainless steel bodies often deliver a more controlled acoustic profile.

Glass

Appeals to design-focused buyers and premium-look markets.

Performs well in content marketing due to visual appeal (e.g., “see the water boil”).

Stainless Steel

Fits professional, everyday, and high-reliability use cases.

Strong choice for bundles with coffee tools, travel gear, or heavy-use hospitality segments.

Your marketing can highlight style and transparency for glass, or durability and performance for steel, depending on brand positioning.

Glass

Requires reinforced packaging and fragile-handling processes.

Shipping costs may be slightly higher due to protection needs.

Stainless Steel

Stronger against transit stress.

Easier to standardize for OEM/ODM product families.

Lower after-sales damage rates improve resale and warranty metrics.

From an export supply perspective, stainless steel kettles generally yield lower operational risk and better consistency in large batches.

| Feature | Glass Electric Kettle | Stainless Steel Electric Kettle |

|---|---|---|

| Durability | Moderate | High |

| Heat Retention | Standard | Better |

| Safety | Highly inert | High with food-grade steel |

| Cleaning | Shows stains easily | Easier long-term care |

| Aesthetic | Visual appeal | Professional and versatile |

| Noise | Audible boiling | Generally quieter |

| Packaging | Requires fragile care | More robust |

| Export Reliability | Higher risk | Lower risk |

Choose glass if you’re targeting:

Aesthetic-driven consumers

Home lifestyle and design audiences

Visual product content for overseas campaigns

Choose stainless steel if you’re targeting:

Durability and frequent use

Export markets with varying water quality

OEM/ODM and private-label stability

There is no single “best” material for all use cases. In practical product engineering and long-term reliability terms, stainless steel electric kettles typically deliver broader performance benefits including durability, heat retention, export shipping resilience, and quieter operation.

Glass Kettles excel in visual experience and lifestyle appeal, making them strong performers in markets where appearance and design matter most.

For overseas independent brands, combining both material options in your product lineup with clear marketing positioning and tailored maintenance guidance can maximize sales across diverse customer segments.